Personal, Commercial, and Industrial Shrink Wrap Applications Each Require Different Gear

Did you know you could shrink wrap your car? Your boat? Your… Nuclear reactor turbine? It seems like everything can be shrink wrapped. Wherever there’s an object of any size that needs to be protected from the elements, there’s an opportunity to apply this technique for keeping property safe. That’s not to say shrink wrapping is the same for each of these instances, though. Personal, commercial, and industrial shrink wrap require distinct processes and different sets of equipment to get the job done.

Here’s a rundown of the types of tools and application methods common in each of these areas.

Personal Shrink Wrap Equipment

The first is shrink tubing. Shrink tubing is shrink wrap that comes in the form of a continuous tube wrapped around a cardboard roll. To shrink wrap something with this method, you simply unwind some of the shrink tubing, slip the object inside, and cut that section of tubing off of the roll. You can then heat the object with a heat gun or oven to shrink the shrink wrap. There’s also electric shrink tubing—cut off a section, slip it around some loose wires, and apply heat to bind them together and insulate them.

A similar application method is single wound shrink wrap. This is the industry term for shrink wrap that’s just wound onto the roll flat instead of as a tube. This is often used in packaging machines—you may have seen it holding together cans of liquid or pieces of firewood. It’s also the variety of shrink wrap you would use to wrap larger objects, such as your car or boat.

Shrink bags are possibly the easiest method of applying personal shrink wrap. Simply place a product into the bag, seal the open end, and heat the wrap so it shrinks. This application is great for shrink wrapping and then shipping individual products if you run an ecommerce shop.

These methods are all great for personal use because they require so little equipment. A sealer lets you seal openings in the wrap to create an enclosed package. Then you can apply heat with a heat gun, which you can find for around as little as $50. Add a film dispenser to make the shrink wrap easy to pull off the roll, and packaging items becomes a breeze.

Commercial Shrink Wrap Equipment

The next step up is commercial shrink wrap. When you start moving up from low output to medium and high output operations, you’ll need new equipment to keep up.

One of the biggest ways to speed up your shrink wrap process is with a shrink tunnel. This device lets you place an item through a kiln that evenly heats the shrink wrap, removing time and inconsistency from the process. Shrink tunnels come in a wide variety of sizes. Some are small standalone units which a small business owner might use to quickly package products for shipments. Larger ones are often near the end of a product line in a factory, shrink wrapping the goods you see in stores.

Similarly, you can also invest in a conveyor to optimize the process by combining it with a film dispenser, sealer, and shrink tunnel. This creates a complete commercial shrink wrap system, where you can efficiently wrap, seal, heat, and move an object into packaging.

Industrial Shrink Wrap Equipment

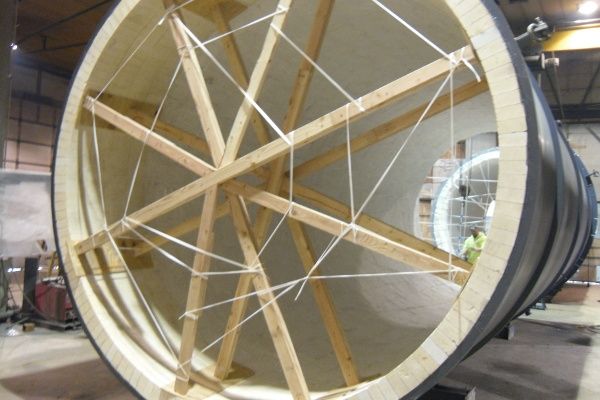

Then there’s industrial shrink wrap. This is quite a different sort of operation than anything we’ve described here, in that the object being wrapped is often much larger. Whether it’s a component of a power plant generator, a jet plane, or a wind turbine, industrial shrink wrap often deals with objects far too large to simply put through a shrink tunnel.

As a result, you have to go back to the heat gun. However, these projects typically use much thicker shrink wrap that requires more heat to shrink. The heat gun you got for personal use won’t cut it for industrial shrink wrap. Instead, you’d have to invest in a heat gun specifically produced for industrial shrink wrap, which costs hundreds of dollars.

- What support structures they need to erect around the object before wrapping

- Where they will cut and fold seams

- Where they will start the heating process

- In what directions and patterns they will move the heat guns to ensure even shrinking

- What temperature settings they’ll use on their heat guns

- Where they’ll install vents and other openings if necessary

This can be a very involved and dangerous process if undertaken by someone who doesn’t know what they’re doing. If it’s an outdoor project, using too high a heat setting can start a fire. On a windy day this can cause pieces of burning shrink wrap to blow away and spread the flames. If it’s an especially large and heavy object, it may need to be hoisted up with a crane.

That’s why, if you’re considering utilizing industrial shrink wrap, you want a team of experienced technicians with years of shrink wrap projects under their belts. Luckily for you, you’ve found just such a team.

Unlimited Shrinkwrap has been wrapping all manner of objects with personal, commercial, and industrial shrink wrap in McHenry, IL and the greater Chicago area for over a decade. Whether you want to wrap your personal boat or you’re searching for a contractor to help your company shrink wrap heavy machinery for transport, one thing’s for sure—Unlimited Shrinkwrap has all the equipment you could ever need to get the job done. That means you don’t have to sink thousands of dollars into getting it yourself. Give us a call at 815-759-8944 and explore your options today!